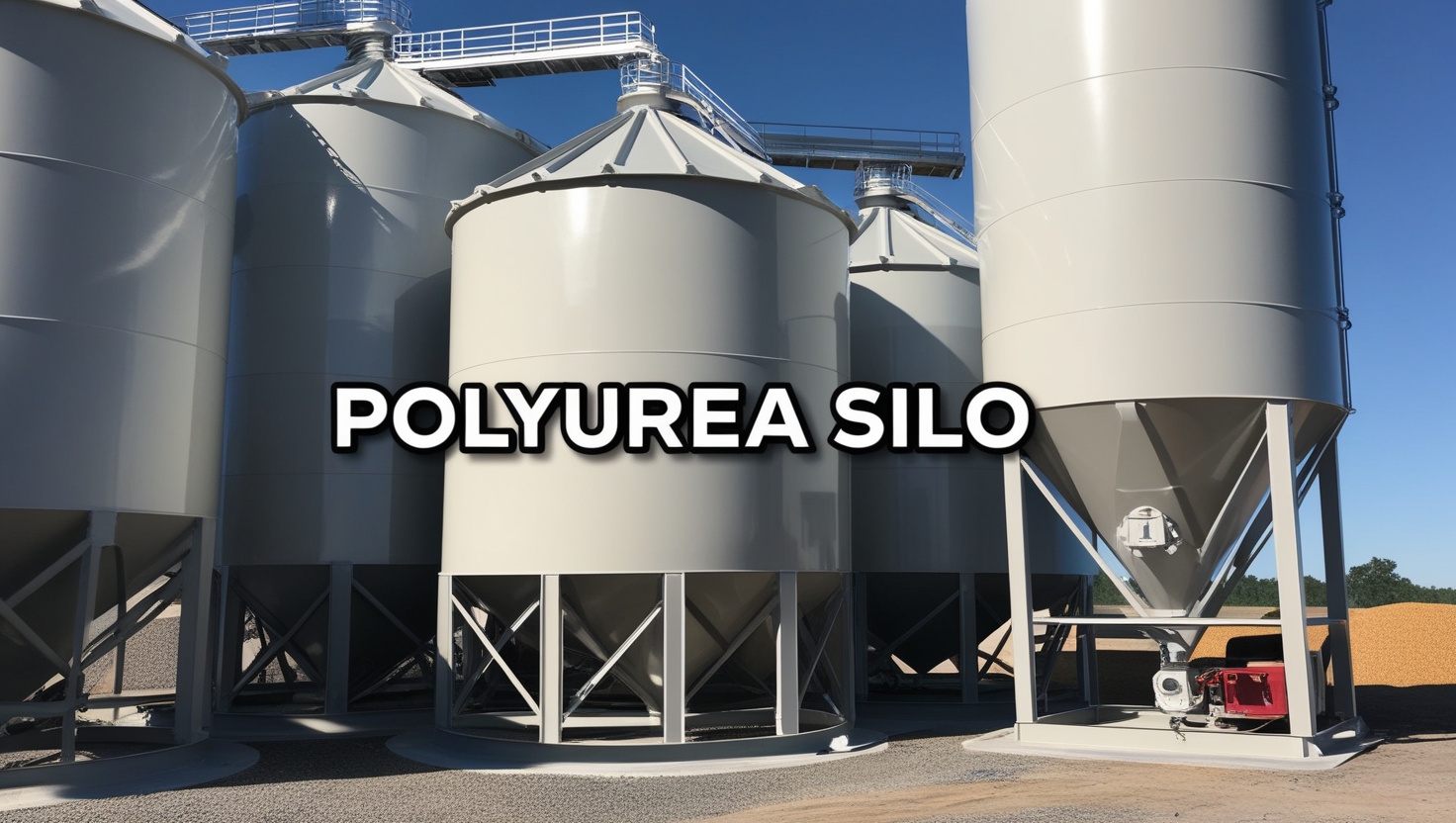

In recent years, the push for sustainable and eco-friendly construction solutions has grown significantly. Among these, Green Future Polyurea Silo stands out as a groundbreaking innovation that not only addresses the need for durable storage solutions but also aligns with environmental goals. Polyurea, a versatile and robust material, is being increasingly utilized for creating silos that offer a host of benefits in terms of durability, safety, and environmental friendliness. But what exactly is a polyurea silo, and why is it gaining traction as the storage solution of the future? Let’s explore.

What is a Polyurea Silo?

A Polyurea Silo is a type of industrial storage container that utilizes polyurea coatings or linings to enhance its performance. Polyurea is a fast-curing polymer that is known for its excellent waterproofing properties, chemical resistance, and durability. These silos are primarily used for storing bulk materials like grain, chemicals, aggregates, and liquids. By incorporating polyurea coatings, the silo can maintain its structural integrity for a much longer time compared to traditional silo materials, reducing maintenance and enhancing safety.

The Green Future of Polyurea Silos

The term “Green Future” refers to the eco-friendly attributes of polyurea-coated silos. These storage units are designed to help businesses achieve their sustainability goals. Let’s break down how polyurea silos are contributing to a greener future.

Environmental Benefits of Polyurea

Polyurea coatings are not just durable and efficient—they are also environmentally friendly. Unlike traditional coatings that might contain harmful chemicals or require excessive energy for application, polyurea coatings are low in volatile organic compounds (VOCs), reducing their impact on the air quality during application. Furthermore, the longevity of polyurea means that the silo’s need for repairs and replacements is drastically reduced, leading to fewer resources used over time.

Energy Efficiency in Storage

The Green Future Polyurea Silo is designed with energy efficiency in mind. Polyurea’s insulating properties help maintain a stable internal temperature, preventing the contents from deteriorating or losing quality due to extreme temperature fluctuations. This minimizes the need for energy-intensive climate control systems and reduces the carbon footprint of the storage process.

Reduced Waste and Maintenance

The durability of polyurea linings significantly extends the life cycle of a silo. Traditional silos might require frequent repairs or even complete replacements due to wear and tear, which creates unnecessary waste. On the other hand, polyurea-coated silos can last for decades without major maintenance, reducing the amount of materials used over time and minimizing the environmental impact associated with silo replacement.

Advantages of Green Future Polyurea Silos

1. Durability and Longevity

One of the standout features of Green Future Polyurea Silos is their superior durability. Polyurea coatings can withstand extreme weather conditions, heavy impacts, and abrasion. This makes the silos highly resistant to damage from environmental factors like rain, snow, UV radiation, and high winds, ensuring that the silo remains intact and functional for many years.

2. Enhanced Protection Against Corrosion

Corrosion is a significant issue for many industrial storage containers, particularly those exposed to harsh chemicals or moist environments. Polyurea provides excellent protection against corrosion, as it forms a seamless, flexible membrane that acts as a barrier between the silo’s structure and external corrosive elements. This significantly reduces the likelihood of rust and deterioration, keeping the contents safe and secure.

3. Faster Installation and Cost-Effectiveness

Polyurea coatings cure quickly, allowing for faster installation times. Unlike traditional coatings that might require extended curing periods or multiple layers, polyurea provides an efficient, single-coat application. This means that businesses can get their silos up and running more quickly, reducing downtime and increasing operational efficiency. In the long term, the durability of polyurea translates to lower maintenance and replacement costs, offering a more cost-effective storage solution.

4. Improved Safety

Safety is a top priority in industrial settings, and polyurea-coated silos contribute to a safer working environment. Polyurea’s non-toxic nature and low VOC content reduce the risk of harmful emissions during installation. Additionally, the smooth, seamless coating minimizes the risk of contaminants accumulating on the surface, preventing the growth of mold or bacteria that could pose a hazard to both workers and the stored materials.

Applications of Green Future Polyurea Silos

1. Agriculture

In the agricultural sector, polyurea-coated silos are being widely adopted for grain storage. The ability of polyurea to protect against moisture and temperature fluctuations helps preserve the quality of stored grains for longer periods. These silos are also resistant to pests, ensuring that grains remain free from contamination.

2. Chemical Industry

Polyurea linings are ideal for the storage of chemicals and hazardous materials. The resistance to chemical corrosion and the ability to create a seamless, impermeable barrier makes polyurea-coated silos perfect for safely storing substances like fertilizers, acids, and other industrial chemicals.

3. Mining and Aggregates

Polyurea silos are also used in the mining industry for the storage of aggregates and other bulk materials. The strength and abrasion resistance of polyurea coatings ensure that these silos can withstand the harsh conditions of mining environments without compromising their performance.

4. Waste Management

In the waste management industry, polyurea-coated silos are used for storing various forms of waste, including hazardous and non-hazardous materials. The chemical resistance of polyurea ensures that harmful substances do not leak into the environment, helping to prevent soil and water contamination.

The Future of Green Future Polyurea Silos

As the world continues to prioritize sustainability and environmental conservation, Green Future Polyurea Silos are positioned to play a key role in the future of industrial storage. The combination of eco-friendly materials, energy efficiency, and long-lasting durability makes polyurea-coated silos an ideal choice for businesses looking to reduce their environmental footprint while maintaining high standards of storage safety and performance.

Expanding into New Industries

As industries across the globe continue to adopt greener technologies, the use of polyurea in silo construction will likely extend into new sectors. Industries such as renewable energy, food storage, and pharmaceuticals may soon find polyurea-coated silos to be a valuable asset in their operations, further promoting sustainability in a wide range of fields.

Innovations in Polyurea Coatings

The future also holds potential for advancements in polyurea technology itself. As research into new materials and formulations continues, polyurea coatings may become even more efficient, durable, and environmentally friendly. This could lead to further improvements in silo performance and even broader applications across various industries.

Frequently

What makes Green Future Polyurea Silos eco-friendly?

Polyurea silos are eco-friendly because they are made from low VOC materials, reduce the need for frequent repairs or replacements, and offer superior durability, which helps minimize waste.

How long do polyurea-coated silos last?

Polyurea-coated silos are known for their longevity. With proper maintenance, they can last for decades, reducing the need for replacements and minimizing environmental impact.

Can polyurea silos be used for all types of materials?

Yes, polyurea silos are versatile and can be used for storing a wide variety of materials, including grains, chemicals, aggregates, and waste, making them suitable for multiple industries.

Are polyurea coatings safe to apply?

Yes, polyurea coatings are safe to apply. They have low toxicity, emit few volatile organic compounds (VOCs), and cure quickly, reducing the environmental and health risks associated with their application.

Do polyurea-coated silos require a lot of maintenance?

No, polyurea-coated silos require minimal maintenance due to their durability and resistance to corrosion, abrasion, and environmental wear. This reduces long-term costs.

What are the cost benefits of using Green Future Polyurea Silos?

The initial cost of polyurea-coated silos may be slightly higher than traditional silos, but the long-term savings in terms of reduced maintenance, energy efficiency, and extended service life make them a cost-effective investment.

Conclusion

The Green Future Polyurea Silo represents a significant step toward more sustainable and efficient storage solutions. With their outstanding durability, environmental benefits, and cost-effectiveness, polyurea silos are becoming an increasingly popular choice for industries that prioritize longevity and sustainability. As more sectors adopt polyurea technology, the future of industrial storage looks greener, more efficient, and more secure.