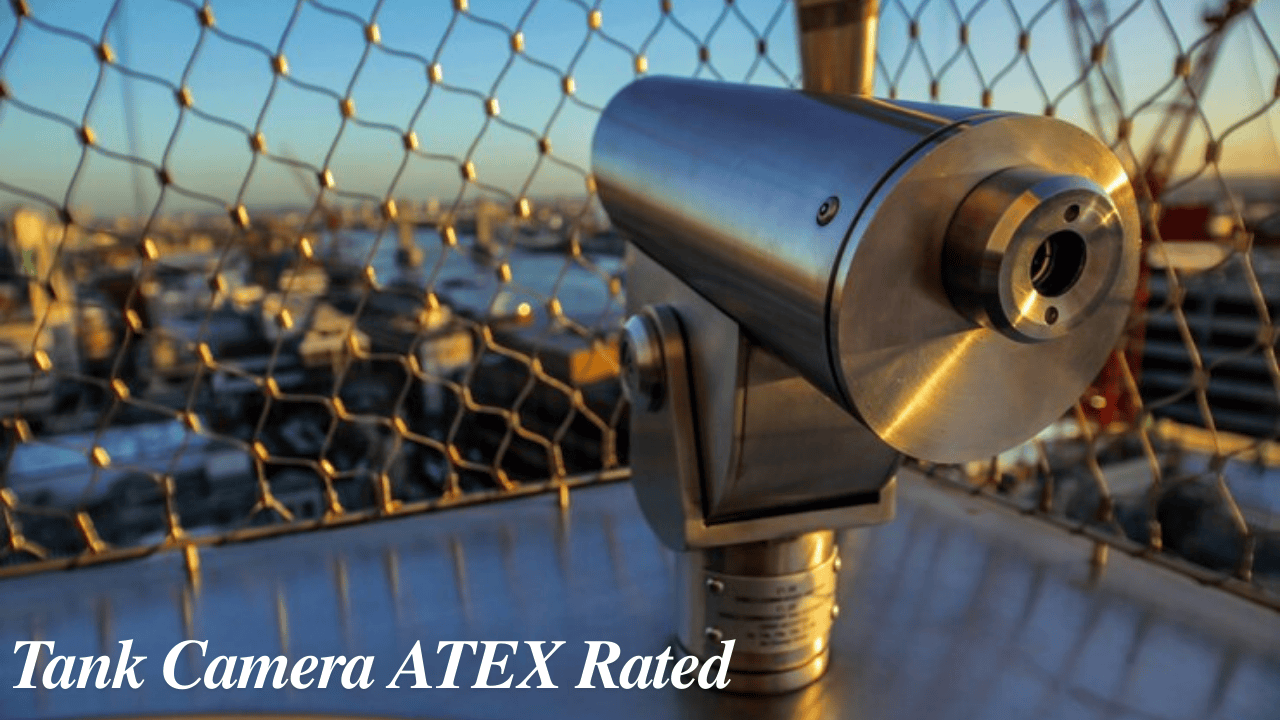

Industrial inspection requires highly specialized equipment, especially in hazardous and hard-to-reach environments. One such game-changer is the Subzero Industrial Tank Camera ATEX Rated, designed for safe and effective inspections in flammable or explosive environments. This camera offers an innovative solution, combining safety, precision, and resilience in extreme conditions. Whether you’re in oil and gas, chemical processing, or pharmaceutical manufacturing, the Subzero Industrial Tank Camera ATEX Rated is essential for safe, efficient inspections.

Introduction to the Subzero Industrial Tank Camera ATEX Rated

Industrial cameras face unique demands in hazardous environments, where safety standards are non-negotiable. The Subzero Industrial Tank Camera ATEX Rated stands out for its rugged design and compliance with the ATEX Directive, a critical certification in Europe that ensures equipment safety in explosive atmospheres. Engineered to withstand subzero temperatures and flammable conditions, this camera is essential for thorough inspections in tanks, pipelines, and storage facilities.

Key Features of the Subzero Industrial Tank Camera ATEX Rated

The Subzero Industrial Tank Camera ATEX Rated is packed with advanced features that make it reliable, robust, and safe for hazardous environments.

- ATEX Certification: The ATEX rating confirms the camera is safe to use in explosive atmospheres.

- Subzero Operating Capability: Built to function effectively in extremely low temperatures, this camera is ideal for industries operating in cold climates.

- High-Resolution Imaging: It delivers sharp, clear images, crucial for accurate inspections.

- Long Durability: Designed with industrial-grade materials to withstand wear and tear in harsh conditions.

- Versatile Mounting Options: The camera’s flexible mounting options facilitate inspections in hard-to-reach areas.

What Makes ATEX Rating Essential for Industrial Cameras?

ATEX certification ensures that equipment is safe to use in explosive or flammable environments. This certification is particularly vital in industries like oil and gas, pharmaceuticals, and chemical processing. The ATEX rating means that the Subzero Industrial Tank Camera has been rigorously tested and meets stringent safety standards, reducing the risk of sparks or explosions during inspections.

Why Choose a Subzero Industrial Tank Camera?

A camera built for subzero environments can significantly enhance safety and operational efficiency. Subzero Industrial Tank Cameras are indispensable for facilities located in colder regions or those handling temperature-sensitive substances. This camera can withstand severe cold without compromising image quality or functionality, ensuring consistent, reliable inspections even under challenging conditions.

Applications of the Subzero Industrial Tank Camera ATEX Rated

The Subzero Industrial Tank Camera ATEX Rated is widely used across several industries that demand precision, safety, and durability.

Oil and Gas Industry

In the oil and gas industry, safety is paramount. The ATEX-rated camera provides a non-intrusive, safe inspection solution for storage tanks, pipelines, and other critical infrastructure, detecting leaks, corrosion, and other issues that could otherwise lead to catastrophic failures.

Chemical Processing

Chemical plants house volatile substances, making them prone to explosions and fires. The Subzero Industrial Tank Camera allows plant operators to inspect equipment and tanks without the risk of igniting volatile chemicals, enabling safer and more thorough inspections.

Pharmaceutical Manufacturing

Stringent regulations require pharmaceutical facilities to maintain a high standard of safety and cleanliness. The ATEX-rated camera can safely operate in zones where volatile gases are present, helping manufacturers maintain regulatory compliance without sacrificing safety.

Food and Beverage Processing

Many food and beverage processing facilities handle flammable ingredients and operate in chilled environments. A subzero-rated, explosion-proof camera can ensure safety and thorough inspection without disrupting the delicate balance of temperature-sensitive environments.

Mining and Refining

Mining environments often involve explosive gases and rugged conditions, and traditional inspection equipment may not suffice. The Subzero Industrial Tank Camera ATEX Rated offers a durable, safe solution for inspecting deep mines, refining machinery, and other sensitive areas in the mining sector.

How to Maximize Safety and Efficiency with an ATEX-Rated Camera

ATEX-rated cameras are designed to meet strict safety standards. To maximize their effectiveness, it’s essential to ensure they are used correctly and maintained regularly. Here’s how to get the most out of your Subzero Industrial Tank Camera:

- Regular Calibration: Ensure the camera is calibrated for optimal performance.

- Routine Inspections: Regular inspections of the camera itself can prevent malfunctions.

- Proper Storage: Store the camera in a clean, dry place to maintain its longevity.

- Follow Manufacturer’s Guidelines: Adhere to the operational guidelines to prevent damage or accidental misuse.

Subzero Industrial Tank Camera ATEX Rated: A Step-by-Step Guide for Use

Using the Subzero Industrial Tank Camera effectively requires understanding its capabilities and limitations. Here’s a basic step-by-step guide:

- Step 1: Set up the camera in the specified location, using the appropriate mounting bracket if necessary.

- Step 2: Connect the camera to the inspection monitor or control unit, ensuring all connections are secure.

- Step 3: Power on the camera, allowing it to adjust to the environmental conditions.

- Step 4: Conduct a preliminary scan to check for any obstructions or anomalies.

- Step 5: Adjust the camera’s position or settings if needed, based on the specific inspection requirements.

Maintaining the Subzero Industrial Tank Camera for Longevity

Maintaining an industrial camera that operates in extreme conditions is critical for performance. Proper maintenance will not only ensure the camera’s reliability but also extend its life, saving costs in the long run.

- Routine Cleaning: Use appropriate, non-abrasive cleaning agents to remove any accumulated dust or debris.

- Temperature Control: After each use, allow the camera to stabilize at room temperature to prevent condensation.

- Component Inspection: Regularly check for wear on essential components like the lens and casing.

- Firmware Updates: Stay up-to-date with firmware updates to ensure the camera’s software is optimized for performance.

Advantages of the Subzero Industrial Tank Camera ATEX Rated

Using an ATEX-rated camera designed for subzero conditions brings several advantages:

- Enhanced Safety: Reduced risk of ignition in volatile environments.

- Improved Inspection Efficiency: Clear, high-resolution imaging allows for quicker, more accurate assessments.

- Cost Savings: By minimizing the need for shutdowns, this camera reduces downtime costs.

- Operational Reliability: Designed to withstand harsh conditions, these cameras offer unmatched reliability in demanding environments.

Key Considerations Before Purchasing a Subzero Industrial Tank Camera

When purchasing an ATEX-rated camera, it’s crucial to evaluate its specifications and compatibility with your specific industrial environment.

- ATEX Zone Classification: Ensure the camera is certified for the specific ATEX zone in your facility.

- Temperature Range: Confirm that the camera’s subzero capability meets the lowest temperatures in your facility.

- Resolution and Image Quality: Choose a camera with high enough resolution for the level of detail required in your inspections.

- Connectivity: Assess the camera’s connectivity options, including remote access if needed.

Conclusion

The Subzero Industrial Tank Camera ATEX Rated is a vital asset for industries requiring safe and reliable inspection solutions in hazardous environments. Its robust design, combined with ATEX certification and subzero capabilities, makes it invaluable for industries like oil and gas, pharmaceuticals, and chemical processing. By ensuring both safety and precision, this camera plays a crucial role in maintaining operational efficiency and compliance in some of the world’s most challenging work environments.

FAQs

How does ATEX certification benefit industrial tank cameras?

ATEX certification ensures that the camera is safe for use in potentially explosive environments, reducing the risk of accidents in hazardous locations.

What industries benefit most from the Subzero Industrial Tank Camera ATEX Rated?

Industries such as oil and gas, chemical processing, mining, and pharmaceuticals benefit greatly due to the camera’s ability to operate safely in extreme conditions.

Can the Subzero Industrial Tank Camera operate in freezing temperatures?

Yes, it is specifically designed for subzero conditions, maintaining full functionality even in freezing environments.

What maintenance is required for the Subzero Industrial Tank Camera?

Routine cleaning, temperature stabilization, component inspections, and firmware updates are recommended to keep the camera in peak condition.